Experts in Wet Process Equipment,

Wet Bench Design and Manufacturing

Wet Bench Design and Manufacturing

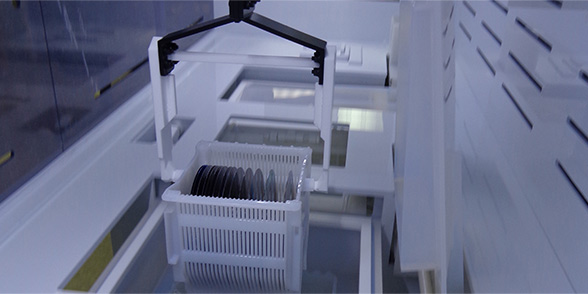

PRECISION-CONTROLLED SEMI-AUTO SYSTEM: OPTIMAL EFFICIENCY & SAFETY

AUTOMATED WET BENCH SYSTEM:

PRODUCTIVITY MEETS INNOVATION

AUTOMATED DRY-TO-DRY SYSTEM:

SPEED & PRECISION COMBINED

SEMI-AUTO WET BENCH WITH IPA DRYER

FOR ENHANCED PROCESSING

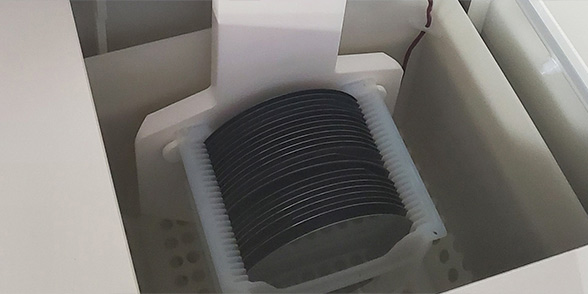

INNOVATIVE IPA VAPOR DRYER:

QUICK, RELIABLE & ECO-FRIENDLY

AUTOMATED PRECISION CLEANING SYSTEM

FOR EXCEPTIONAL PARTS CLEANING

MANUAL WET STATION: TAILORED FLEXIBILITY

FOR DIVERSE PROCESSES

CHEMICAL DELIVERY SYSTEM FOR

SECURE & ACCURATE MEASUREMENT

PRECISION-CONTROLLED SEMI-AUTO SYSTEM: OPTIMAL EFFICIENCY & SAFETY

AUTOMATED WET BENCH SYSTEM:

PRODUCTIVITY MEETS INNOVATION

AUTOMATED DRY-TO-DRY SYSTEM:

SPEED & PRECISION COMBINED

SEMI-AUTO WET BENCH WITH IPA DRYER

FOR ENHANCED PROCESSING

INNOVATIVE IPA VAPOR DRYER:

QUICK, RELIABLE & ECO-FRIENDLY

AUTOMATED PRECISION CLEANING SYSTEM

FOR EXCEPTIONAL PARTS CLEANING

MANUAL WET STATION: TAILORED FLEXIBILITY

FOR DIVERSE PROCESSES

CHEMICAL DELIVERY SYSTEM FOR

SECURE & ACCURATE MEASUREMENT

Semiconductor manufacturing and the overall technology industry demands precision, reliability, and consistency.

The production of cutting-edge electronic microdevices requires stringent quality control, and any variation in the manufacturing process can have a significant impact on product performance. To meet the ever-increasing demand for high-quality products, manufacturers must stay ahead of the curve by implementing advanced process control measures.

As experts in wet process equipment and wet bench system design, Modutek is committed to providing innovative solutions that enable our customers to achieve the highest levels of precision, efficiency, and quality.

Semiconductor manufacturing and the overall technology industry demands precision, reliability, and consistency.

The production of cutting-edge electronic microdevices requires stringent quality control, and any variation in the manufacturing process can have a significant impact on product performance. To meet the ever-increasing demand for high-quality products, manufacturers must stay ahead of the curve by implementing advanced process control measures.

In-house engineering experts, state-of-the-art technology, and end-to-end fabrication capabilities are all designed and built into Modutek’s systems to ensure quality, high reliability, direct customer support.

Wet process equipment and systems from Modutek are compact and efficient, and more cost-effective.

Modutek has been providing equipment and systems to meet the needs of technology customers continuously for over 40 years.

Experienced In-house engineering experts work directly with customers to continually improve products and provide solutions.

Modutek provides products that allow customers to achieve optimal control for consistent and repeatable processing leading to higher-quality output.

Modutek provides equipment and systems that consistently perform at a high level which provides reliable performance, minimizes downtime, and improves facility performance and profitability.

All products come with comprehensive technical support and training, including service calls and remote troubleshooting.

In-house engineering experts, state-of-the-art technology, and end-to-end fabrication capabilities are all designed and built into Modutek’s systems to ensure quality, high reliability, direct customer support.

Modutek has been providing equipment and systems to meet the needs of technology customers continuously for over 40 years.

In addition to equipment offerings, Modutek provides comprehensive support services, including startup, and training with technical assistance. Our team of experts ensures that customers receive the necessary guidance and support to maximize the benefits of using Modutek’s equipment.